STATE-OF-THE-ART

INDUSTRIAL FANS

Reitz India specialises in producing scientifically designed

modular fans (size up to 10,000 kW) that boast an optimum

price-performance ratio besides setting new benchmarks in performance,

energy efficiency, and durability.

STATE-OF-THE-ART

INDUSTRIAL FANS

Reitz India specialises in producing scientifically designed modular fans (size up to 10,000 kW) that boast an optimum price-performance ratio besides setting new benchmarks in performance, energy efficiency, and durability.

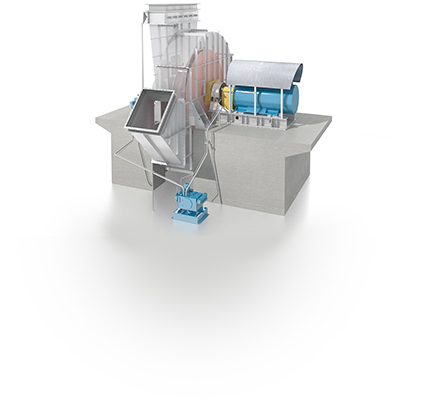

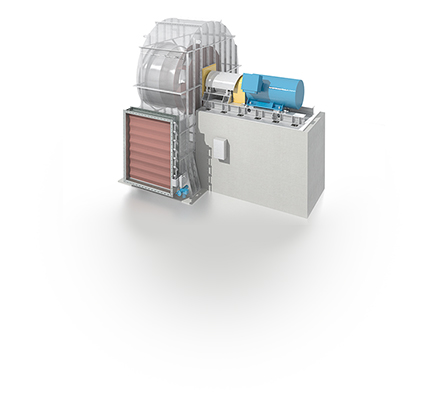

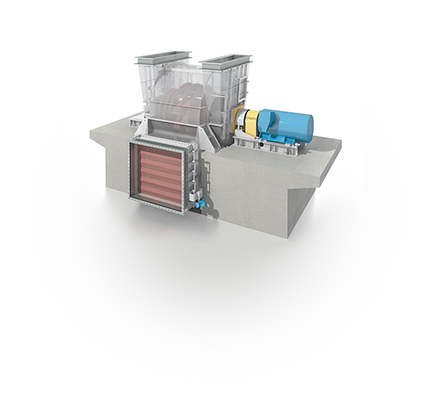

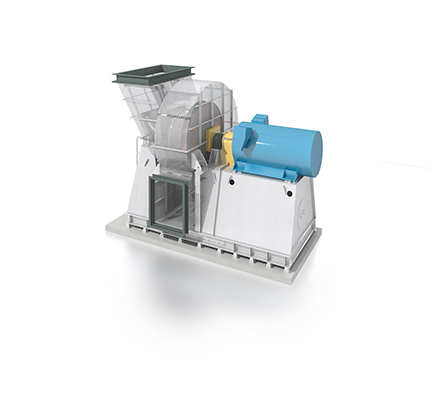

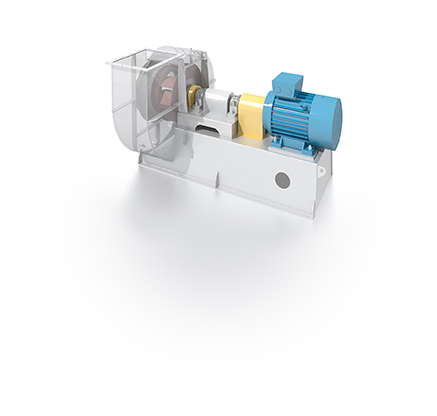

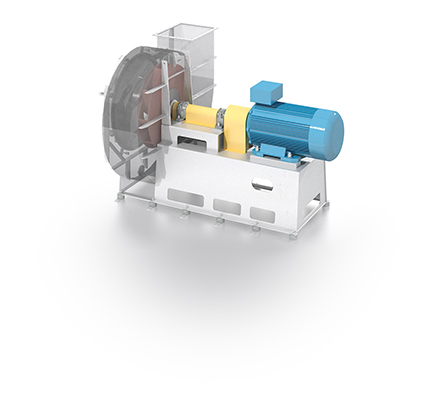

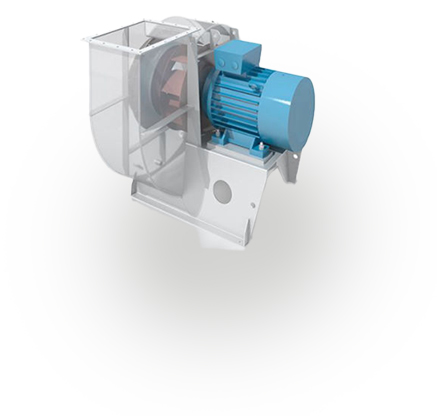

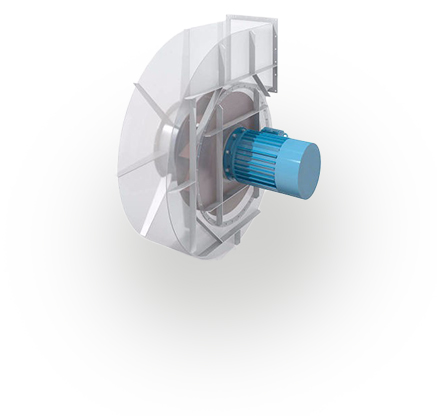

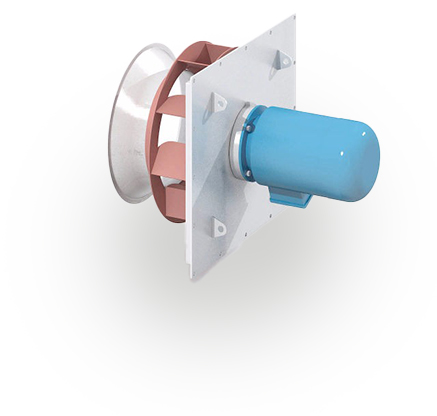

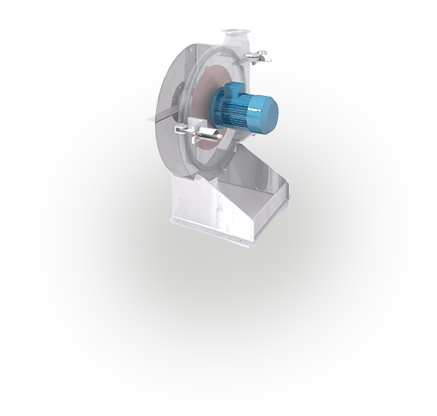

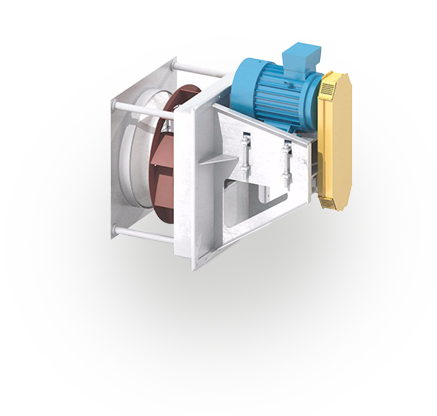

MODELS

In addition to an attractive price-performance ratio, REITZ radial fans also offer a particularly broad product range, thanks to their modular design. All models are available in individual designs with drive systems, sound insulation and other comprehensive accessories.

ACCESSORIES

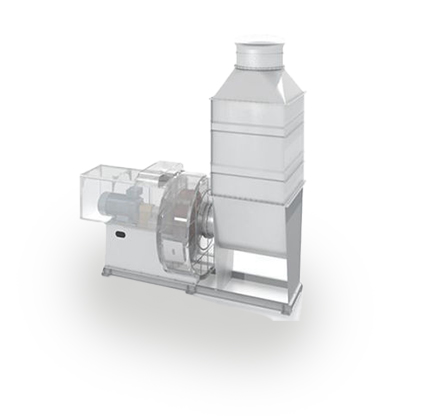

VENTILATION SYSTEM DIAGRAM

DESIGNS

Typical REITZ flexibility in design and production does not only mean we manufacture fans of every size up to 10,000 kW with special drives (e.g. steam turbine) or in stainless steel. We offer you practically every model in the design or design combination tailored to perfectly suit to your application.

display:none

In processes involving a system inlet pressure of at least 0.5 bar, a solid, pressure-resistant design is required to ensure that welds, walls, flanges, bolts and other components can withstand the system pressure.

RELIABLE PRESSURE RESISTANCE

The components are continuously welded on both sides in the pressure-resistant design. Materials are selected and wall thicknesses are calculated to meet requirements.

Pressure-resistant fans from REITZ are subject to the Pressure Equipment Directive, with welds undergoing dye penetration testing and a pressure test. All relevant testing documents are carefully archived.

Pressure Resistant

In processes involving a system inlet pressure of at least 0.5 bar, a solid, pressure-resistant design is required to ensure that welds, walls, flanges, bolts and other components can withstand the system pressure.

RELIABLE PRESSURE RESISTANCE

The components are continuously welded on both sides in the pressure-resistant design. Materials are selected and wall thicknesses are calculated to meet requirements.

Pressure-resistant fans from REITZ are subject to the Pressure Equipment Directive, with welds undergoing dye penetration testing and a pressure test. All relevant testing documents are carefully archived.

Pressure Shock Proof

Pressure shock-proof designs up to 10 bar (absolute) are part of our proven delivery programme. Continuously housing welds and stiffeners also provide the required stability.

NO EXPLOSION WEAK POINTS

In the event of a pressure shock occurring within the range of 0.2 to 10 bar, REITZ pressure shock-proof fans can withstand the pressure without rupturing. Minor warping can occur. REITZ has manufactured several hundred pressure shock-proof fans to date in the range up to 10 bar.

Housings are continuously welded both externally and internally, while wall thicknesses, flanges and bolts are adapted to suit the calculated requirements. Additional protection is provided by all-round radial stiffeners. Welds are subjected to standard dye penetration testing, and all relevant testing documents are carefully archived.

Explosion Protected

Special safety precautions need to be taken where combustible dust and gases are conveyed or may be present in the environment. Pursuant to the currently valid ATEX directive, explosion-protected designs from REITZ are equipped with all necessary security features.

Characteristics which ensure the high safety standard include a constructional safety that is adapted to the required ATEX category, special seals for the shaft passage, continuous weld seams, high-quality balancing and provisions for grounding of the fans.

Both the ATEX design for the European area and the spark protection version for fans installed outside the EU comply with the EN 14986:2017 standard (“Design of fans working in potentially explosive atmospheres”). Any such fan is tested and recorded by REITZ quality assurance pursuant to the REITZ explosion protection directive.

On a volunteer basis, REITZ is audited by a certified auditing company at regular intervals in order to fulfil its high quality standards.

Gas-, Liquid- and Dustproof

Absolute tightness is a top priority in the requirements profile when dealing with problematic media such as toxic liquids or gases. With an equally high level of care and know-how, REITZ meets all the relevant safety standards.

OPTIMUM PROTECTION FOR THE ENVIRONMENT

In order to prevent anything escaping to the exterior and ensure that people and the environment enjoy maximum safety, we equip our gas, liquid and dustproof fans with a sealing system which has proven its effectiveness thousands of times in practical applications. In addition to gasproof welding of the housing, shaft passages and flange connections are equipped with reliable sealing technologies such as the multichamber labyrinth seal and, where required, the barrier gas connection or grease seal.

High Temperature Design

Under practical conditions, extremely hot media represent a major challenge for the safe and trouble-free operation of ventilation systems. REITZ has developed unique know-how in this area which discerning plant manufacturers exploit all over the world to ensure the success of their projects.

IDEALLY EQUIPPED AGAINST HOT MEDIA UP TO 500 °C

Extreme process temperatures up to 500 °C pose no problem for REITZ temperature design fans. The special REITZ temperature design, which includes the use of additional cooling, sealing and insulation components, ensures that operation is safe. In addition to other measures, solutions such as the thermal separation of the pedestal and housing or a cooler fan to support the heat flinger and stabilise the bearing temperature are fitted to stabilise the system at extremely high temperatures.

Moreover, REITZ fans are designed for continuous trouble-free operation under extreme exterior temperatures.

Corrosion Protection

REITZ corrosion protection variants offer the highest levels of hygiene and durability. We supply a broad spectrum of effective corrosion protection measures which have proven their reliability under practical conditions and are tailored exactly to meet your application specifications.

PAINT AND SURFACE COATING

Primer, intermediate and top coats

A paint finish is a simple but well-proven form of corrosion protection. All RAL colours and a variety of paint systems are available.

Chrome-plated, nickel-plated, galvanised design

Galvanising with corrosion-resistant layers provides components with reliable protection. There are sound reasons for choosing high-performance chrome, nickel or zinc-based protection, depending on the application and requirement involved.

RUBBER AND SPECIAL COATING

Rubber and special coating with Halar® and Säkaphen®

Halar® is a high-performance thermoplastic fluoroplastic which is highly resistant to chemicals and provides excellent corrosion protection and thermal properties. Halar® is abrasion resistant, has excellent anti-adhesion properties, a smooth, non-porous surface and contains no solvents. Stove enamel finishes from Säkaphen® offer high-end corrosion protection against aggressive media. Säkaphen® guarantees excellent protection against strong acids and alkaline media, particularly at high temperatures.

CHEMICAL SURFACE TREATMENT

The main purpose of chemical treatment is to achieve a high surface quality.

Pickling

Pickling to protect and clean the surface rigorously removes oxides, particularly heat tinting (e.g. in the vicinity of welds), other discolouring and corrosion spots.

Passivating

In the case of steel and many other metals, it may be practical under certain circumstances not to leave development of a protective passivation layer to chance. Creation of the passivation layer is accelerated in a targeted manner through the process.

Electropolishing

Employing an external power source, this electrochemical removal procedure reduces microroughness and improves the smoothness of the metal. As a result, dirt and other residues find it more difficult to stick and the component surfaces can be cleaned more effectively.

MECHANICAL SURFACE TREATMENT

When combined with chemical surface treatments, mechanical processes achieve the required polish and sheen.

Vibratory grinding

Impellers and surfaces in contact with the product are initially pickled and passivated in many cases before achieving an optimum surface quality through vibratory grinding. The workpiece is ground with abrasive media in a vibration container during this, achieving a precise removal of material.

Sandblasting and glass bead blasting

Similar to vibratory grinding, sandblasting and glass bead blasting are employed to achieve maximum homogeneity of surfaces and the side effect of material solidification. Uniform deburring, oil removal, degreasing, descaling, smoothing, polishing, cleaning, rounding of corners and grinding are the corrosion-reducing options this treatment offers.

Control Systems

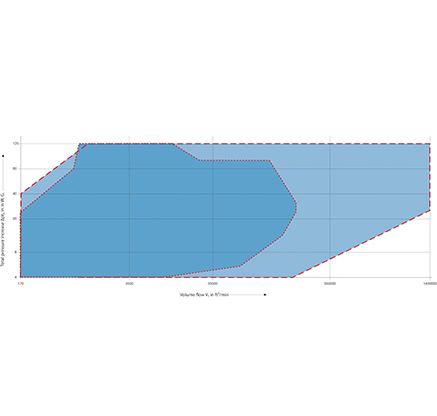

Conventional damper and inlet guide vane control systems are increasingly being replaced by variable speed control systems. There are understandable reasons for this, as energy consumption during variable speed control is only as high as actual required during operation. This results in energy savings and an improved energy balance sheet.

MECHANICAL CONTROL SYSTEMS

Damping with a damper or louvre damper is the easiest way to reduce flow, but the most inefficient in terms of losses. The further the damping elements are closed, the greater the pressure loss. Whereas the additional resistance alters the plant characteristic curve, the fan’s power requirement curve remains unchanged.

Inlet guide vane control generates a pre-whirl through adjusting of the guiding vane. Both the plant characteristic curve and power requirement curve of the fan are altered, relative to the adjusting angle and swirl.

ADVANTAGES OF VARIABLE SPEED CONTROL

100 % needs-based consumption

Linear control characteristic

Quiet running

Perfect start-up behaviour

Mechanical smoothness

VARIABLE SPEED CONTROL

In variable speed control, the pressure is only increased by the exact amount at the respective operating point needed by the system as resistance to realise the required volumetric flow. In ventilation systems with a parabolic characteristic curve, this means savings in excess of 80 per cent at individual operating points without any reduction in efficiency.

REITZ fan systems with variable speed control consist of three precisely coordinated components. Additional costs for the variable speed control system amortise on average within two years through the savings effects.

Existing ventilation systems can be retrofitted with variable speed control during partial modernisation. Talk to your REITZ Retrofit contact!

Wear Protection

Wear protection is a preventive measure to protect high-performance components against abrasive material in the air flow. A positive effect is the increased service life and the avoidance of subsequent costs. REITZ offers an entire spectrum of innovative low-wear measures which take optimum efficiency into consideration.

EFFECTIVE PROTECTION, OPTIMUM EFFICIENCY

Long service periods and high levels of efficiency are absolute prerequisites for efficient plant operation. Unnecessary wear costs millions, and non-optimised efficiency leads to the unnecessary waste of energy. In cooperation with prestigious institutes and technical colleges, the REITZ development department focuses continually for this reason on optimisation through the use of improved materials and geometries. One result of this can be seen in service period guarantees of up to 15,000 operating hours for impellers and housing components which is perceptible in the operational reliability and profitability of the production process.

WEAR PROTECTION MEASURES

Low-wear impeller geometries

In the case of severely abrasive media, optimised impeller types ensure a smoother, more uniform flow through the impeller, reducing sticking material and wear processes to a minimum.

Use of suitable materials

We only use particularly robust, high-strength materials of proven quality to ensure that your fans can withstand even the highest levels of stress.

Increasing material thickness

REITZ low-wear fans are distinguished by above-average resistance and durability, both in terms of the increase in the base material thickness and the targeted welding of wear plates in critical areas.

High-precision machining

Particularly careful and uniform machining is required in critical areas such as welds and edges to avoid material sticking and other processes which contribute to wear from the outset.

Protective surface structure and coating

Special surface structures and coatings which are continuously optimised and harmonised in the REITZ measurement centre and labs protect the base material and optimise the conveyance of solids.

INNOVATIVE IMPELLER GEOMETRY SHOWS THE WAY

Achieving the balance between the demands of wear protection and best-possible efficiency is the noble art of engineering. And a high degree of efficiency need not be dispensed with in the case of fans which convey solid material. Efficiency levels which exceed 80 % can also be realistically achieved in these applications, depending on the pressure and flow range.

Water Injection

The best possible way to avoid sticking material in the case of water-soluble media is use of a fan design with water injection, as this enables continuous cleaning during operation or shutdown.

RINSING AND CLEANING WITH WATER INJECTION

Sticking of material can be largely avoided through selection of an appropriate impeller. In addition, the reliable water injection method is available in the case of water-soluble media to reduce material sticking to the bladed impeller and housing to a minimum. Systematically arranged spray lances and nozzles clean the bladed impeller during operation. Moreover, the system is suitable for complete cleaning of the fan which should be realised at regular intervals. Note: Despite the well-engineered injection technology, sticking of material cannot be completely avoided.

Special Design

Different design options are frequently combined with each other for special requirements and application areas. In addition to conventional options, REITZ also provides special designs which represent a class of their own in terms of their drive system, design and additional equipment.

SPECIAL DESIGNS

Sophisticated plant operators prefer to place their trust in REITZ when it comes to special requirements, as they value the performance levels and broad variety of choice. Exceptional solutions and engineering that masters challenges in a careful, conscientious manner are the prerequisites for smooth operation, including in critical application areas. The technical design of our fans is based on DIN 24166. In addition to this, we also meet the requirements of numerous internationally recognised and sector-specific regulations and standards.

DRIVE VARIANTS

In addition to special designs, our portfolio also contains a variety of drive concepts which are tailored exactly in each case to their intended task. From the steam turbine and trial spin drive to the combined double drive, you can obtain the exact highly specialised drive solution you require from us, ensuring that the efficiency, operational reliability and availability of your plant is optimised to a maximum degree.

EQUIPMENT & ACCESSORIES

The difference is in the detail. A small selection of the reliable components and accessories which can be adapted in daily use to suit your needs and requirements includes the following:

Monitoring devices for bearing temperature, vibration, speed, etc.

Freewheels, gears, backstops

Stop brakes

Oil conditioning for sleeve/oil and rolling bearings

Lubrication devices for bearings

Complex sealing concepts with barrier gas supply

Electrical instrumentation and control technology, control cabinets, cabling

Scaffolds, platforms etc. to facilitate access